Microorganisms BX-1 and Compost Plant RA-X (Durable, Low Cost, Easy to Use and Maintain)

Microorganisms BX-1 and Compost Plant RA-X (Durable, Low Cost, Easy to Use and Maintain)

The combination of Microorganisms BX-1 and Compost Plant RA-X, is a solution to treatment of livestock manure. In most cases, manures are simply dumped into the ground or water, contaminating the environment. Sometimes, they are turned into fertilizer, but conventional processes require energy and cost. This technology use BX-1, microorganism that reduce the smell of manure and also fastens the process of converting manure into fertilizer, among other benefits that improve the health and quality of livestock. RA-X, the compost plant, uses relatively simple equipment available in developing countries to mix the manure in fast and energy-efficient way. The output, the fertilizer, is of the quality that can easily be sold in the market, creating jobs and the revenue to cover some of the cost necessary to operate the plant.

Major Features and Benefits

BX-1

BX-1 is a complex fermentation bacteria made through a special manufacturing process that includes lactic acid bacteria, yeast, Bacillus subtilis, etc. Unlike regular lactic acid bacteria and yeast, it exhibits stable performance under a variety of conditions. BX-1's acid resistance nature allows it to enter the intestines, suppress harmful bacteria, promote efficient digestion, and reduce bad odors and harmful components caused by bacteria such as Clostridium perfringens that breaks proteins and amino acids and increases harmful substances such as ammonia, amines, and hydrogen sulfide. The odor of manure and urine is reduced and livestock’s digestion and absorption are improved.

In addition, the mucus fluid in the intestines, such as mucin in the intestinal wall where bacteria live, and the mucus fluid of mucopolysaccharides on the surface of the bacteria, are reduced greatly and converted into lactic acid bacteria and yeast, so less of the stickiness of animal manure is reduced.

Furthermore, the reduction in harmful substances means that less of these are respired from the intestines, which reduces the burden on the organs, expands the peripheral blood vessels, and removes obstacles, allowing for smoother nutritional intake and promoting cell growth. As a result, you can improve the quality of meat, eggs, and milk, promote growth, and improve health.

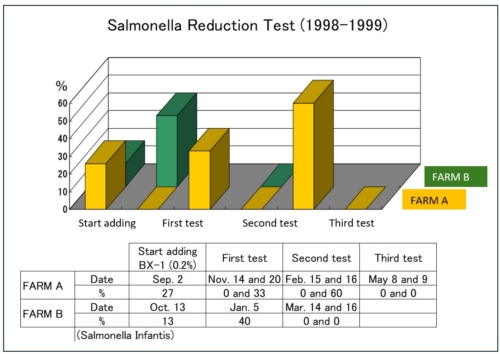

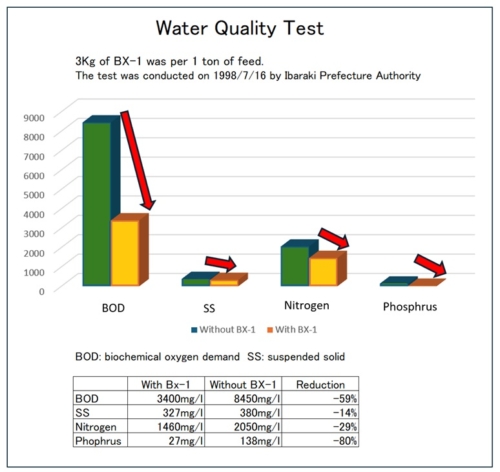

Some of these benefits may be causing reduction of salmonella bacteria and improved water quality, as shown in below charts.

RA-X

|

Used together with BX-1, this machine efficiently composts organic waste such as food waste, livestock manure, and sludge. Normally, these processes require various equipment such as a separator to separate the input manure into solids and wastewater, a fermentation machine to turn the solids into compost, and a septic tank and dehydrator to treat the wastewater, which are expensive and require skills and personnel for maintenance. However, the RA-X can process livestock manure and sludge with just one machine. One of the reasons that the RA-X can perform the treatment by itself is the use of aerobic fermentation, which simplifies water treatment because there is little temperature drop. In addition, the structure of the machine is simple, so the necessary parts can be easily procured in developing countries, there are few breakdowns and maintenance efforts, and electricity and maintenance costs are low. The RA-X is classified as a plant suitable for large-scale industrial mass treatment. |

Technology Data

Competitive advantage

BX-1

1) An excellent complex fermentation bacteria that has been aged over a long period of time.

2) All products are manufactured in-house, from the original bacteria.

3) There is a wealth of experimental data, including Salmonella adhesion tests, highly virulent virus disease inhibition tests, feed efficiency tests, and fertility tests.

4) A track record of presenting papers at academic conferences around the world (Japan Society for Animal Laboratory Science, American Society for Experimental Biology, etc.).

5) Since its release in 1987, there have been no complaints about the product’s effectiveness.

6) High repeat utilization rate.

7) Cheaper than similar products with the same effects.

8) Consulting and support for using BX-1 efficiently can be provided.

9) BX-1 is shipped as dry powder that is easy to handle and manage.

10) Ample record of overseas sales.

RA-X

1) Simple structure makes maintenance easy, with few breakdowns, and low electricity and maintenance costs.

2) Reliable mixing regardless of moisture content. Less temperature drop during mixing, allowing for energy-saving fermentation.

3) Solids and wastewater can be treated simultaneously. Waste can be accumulated up to the height of 1.8m.

4) Sewage treatment system is patented. No compression during mixing, high porosity, and excellent moisture evaporation, which promotes aerobic fermentation.

5) Low fermentation odor dispersion during operation.

6) Wide range machines are available to cope with various types and volume of waste.

7) Aerobic fermentation suppresses the generation of greenhouse gases such as methane gas and nitrous oxide.

8) Odor control is easy, allowing for significant reductions in odor control costs.

Technical maturity / Past record of introduction

BX-1

Since the introduction in 1987, there was no complain about the effectiveness of the product. Average annual sales amount is about 150t per year,

RA-X

RA-X was introduced for customers such as:

– Authority of Kandy District, Sri Lanka (9 locations)

– East Japan JA (Japan Agricultureal Cooperative) Kumiai Shiryo

– Green Base Seisan Cooperative

– Hokkaido Kayabe-gun Mori City

2007: JETRO Feasibility Project of organic waste and sewage water treatment in Kunming City, China

2015: JICA Demonstration Project in Sri Lanka

https://www.youtube.com/watch?v=PI-YbqRrr44

(Video starts about 1min. 10 sec. later.)

2021: JICA Project in Paraguay to support SDG among SMEs

Information on patent related to this technology

BX-1

Ministry of Agriculture, Forestry and Fisheries (MAFF) Certification as Mixed Feed Registered Company

RA-X

2004: Japanese Patent No. 3607252

Company Data

Company data

| Name | Kawashima Co., Ltd. |

| Address | 3765 Kusunoki-cho, Tatebayashi-shi, Gunma-ken, JAPAN |

| Capital | 20.5 million JPY (as of August, 2023) |

| Contact person |

Mr. Kenji Kawashima Tel: +81-77-549-8015 Corporate website:http://www.kawashima.jp |

| Number of employees | 6 |

| Date of company foundation | 15 June 1987 |

| The type of business | Manufacturing |

Modality of business transaction

We are open to diverse kind of conditions depending on the situation of the country.

Kindly inform us your business plan so that we can start the discussion.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Waste treatment and management

- Human Health Technologies : Public health