Ensuring Safe and Stable Water

Supply Utilizing Remote

Monitoring System

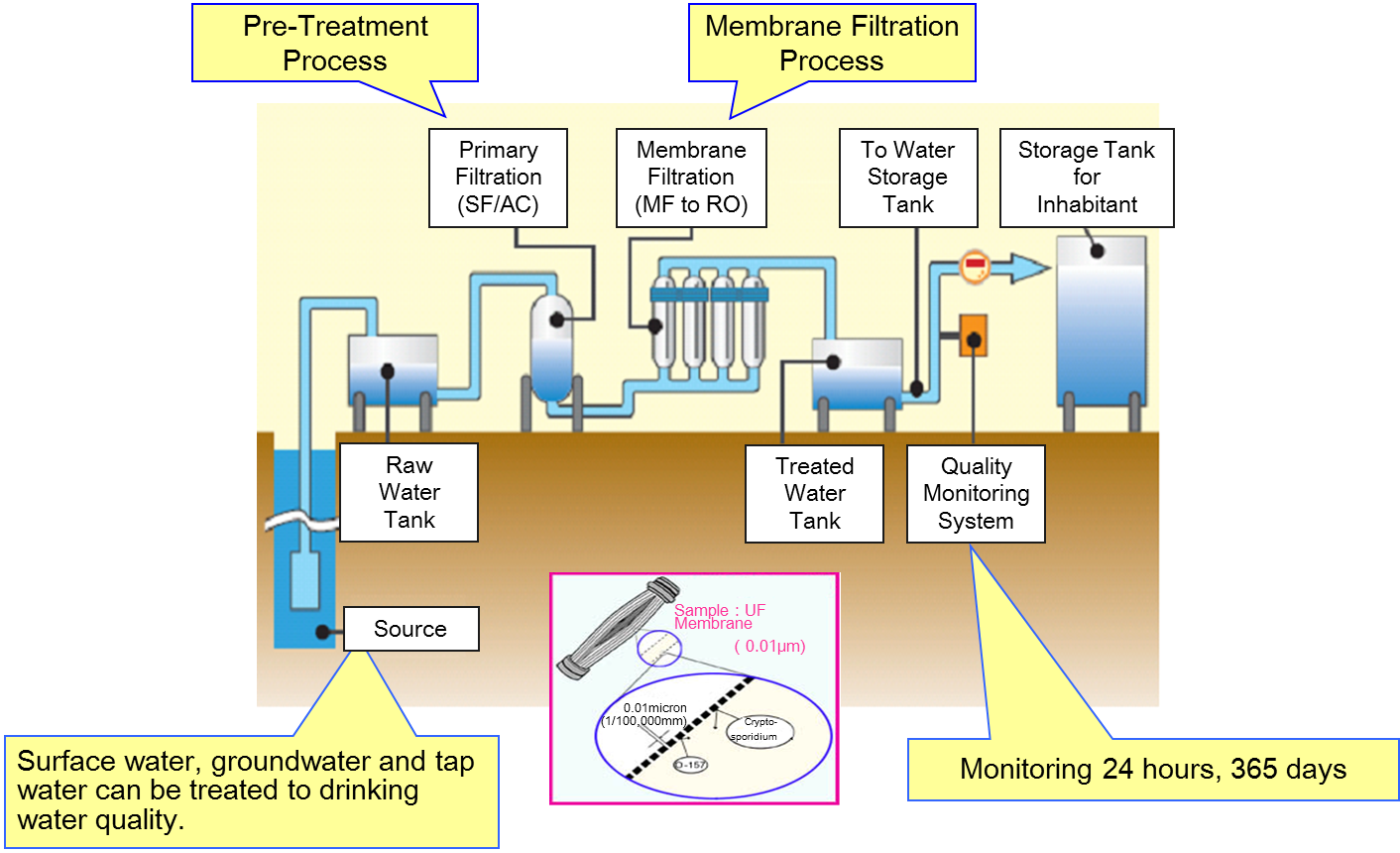

M itsubishi Chemical Aqua Solutions Co., Ltd. has introduced a small-scale, on-site water treatment and supply system, hereinafter referred to as the “System”, that treats water from existing water sources at or near the customer's land and converts it into safe drinking water that meets the quality standards for drinking water. Moreover, the Cloud/Web-based Remote Monitoring System (WeLLDAS™) is equipped to monitor the operating status and water quality. By using this, technical support can be provided remotely from Japan.

Fig. 1 An example of On-site Water Treatment and Supply System

Fig. 1 An example of On-site Water Treatment and Supply System

The System supplies clean water by combining pre-treatment processes and membrane separation technology in an effort to remove contaminants such as bacteria, viruses, anti-chlorine protozoa, iron, arsenic and manganese. The exact process will depend on the quality of the raw water used.

The System can produce an average of 50 and 1,000 m3/day of clean water. The risk of water contamination within the distribution system is low, as the System does not need long distribution pipelines.

In terms of water treatment performance, the System can boost the quality of the water, with each system completely customized for each client.

Major Features and Advantages

I. Safety and Stability

Mitsubishi Chemical Aqua Solutions’ On-site Water Treatment and Supply System, which consists of pre-treatment process and membrane separation technology (see Fig. 2), takes away the contaminants from raw water and converts it into drinking water that is safe to consumers. There is little maintenance and operational commitment thanks to its fully automated features. This ensures steady and stable results.

Fig. 2 Basic treatment process flow

II. Low Start-Up Costs

Since the System is decentralized, the associated initial costs and O&M costs associated are low, as compared to larger, more centralized water treatment systems. No long supply pipelines are necessary and minimal construction costs are involved.

III. Energy Efficient

Not as much energy is required, as compared with large scale systems, when it comes to water intake, treatment and supply. This means that the System contributes to realizing low carbon emission.

I V. Remote Monitoring (WeLLDAS™)

V. Remote Monitoring (WeLLDAS™)

Operational conditions of the System and water quality data can be accessed from any location, not just on-site. The remote monitoring system “WeLLDAS™” is operated from remote areas using a local SIM for mobile, so it is ideal for areas in which access is difficult.

WeLLDAS™ can also be introduced individually to municipal water treatment plants, whether new or existing. It will help water services providers grasp the operational conditions, i.e. water pressure, supply volume, and water quality of both raw and treated water.

WeLLDAS™ has been installed in more than 400 places overseas, including Japan and developing countries.

Fig. 3 Remote Monitoring System “WeLLDAS™”

Product guide: WeLLDAS™ pamphlet_MCAS

Technology Data

Technology data

Possible applications

The System treats existing water sources, such as groundwater, surface water and water from public supply, into drinking water that meets the drinking water quality standards. The System suits individual facilities such as hospitals, residential buildings, schools, communities, etc.

Competitive advantage

- Safe and stable water supply system using membrane technology

As a company with expertise in water treatment engineering, we select and propose the optimal filtration technology for each customer considering the local needs and site situation. We mainly utilize UF membrane, which has tiny pores with a size of 0.005 micron, and by combining with pre-treatment process the System can remove impurities in water physically. Also, the System is fully automated, hence it ensures safe and stable water supply with minimum maintenance and operational effort. - Technical assistance through remote monitoring system (WeLLDAS™)

Each of the System is equipped with a remote monitoring system called, “WeLLDAS™”(See Table 1). With WeLLDAS™, operating status and water quality data are accessible even from remote areas with easy access from PC, Smart phones, etc. It has standardized specifications for global operation in different countries. Since it is automatically measured as long as a communication network can be secured, it is possible to make up for the labor shortage in remoted areas in developing countries. The operation cost of WeLLDAS™ is very economical with local SIMs, but at the same time, it assures high level of security by VPN. Table 1 Features of WeLLDAS™

The monitoring parameters can be checked continuously as long as there is network. Some functions like trend graph and mesh data will offer how a certain parameter(s) varies in a certain period of time or areas (see Fig. 4). If an abnormality is found in the monitored parameter, an alert email will be sent immediately to the person in charge, which will be useful for quick maintenance. It also helps optimize maintenance activities of your plant and is an effective tool for preventive maintenance. Fig. 4 Trend display of operational data (left) and water level monitoring (middle: trend display, right: mesh data)

Performance

We usually design the Systems that have a treatment capacity from 50 to 1,000 m3/day.

The smaller type of membrane filtration unit is also available. Fig. 5 shows the portable unit where water filtration process and several types of faucets are integrated to provide instantly both drinking water and domestic water with local people. Dimension of the unit is W1200mm×D1500mm×H2050mm, and it can produce 20,000 liter of water per day.

Fig. 5 Small type of membrane filtration facility for drinking water

Fig. 5 Small type of membrane filtration facility for drinking water

As for the water treatment performance, our technology can improve the quality of water to meet the customer’s needs, i.e. WHO standards, national guidelines, etc.

Technical maturity / Past record of introduction

As of January 2021, we have installed and operated more than 1,300 on-site water treatment and supply systems in Japan and overseas, such as Kenya, Africa and Myanmar and Vietnam, Southeast Asia.

Fig. 6 Pilot Systems in Kenya

Fig. 7 Pilot Systems in Vietnam

Information on patent related to this technology

N/A

Company Data

Company data

| Name | Mitsubishi Chemical Aqua Solutions Co., Ltd. |

| Address | 2-2, Nihonbashihongoku-cho 1-chome, Chuo-ku, Tokyo |

| Capital | JPY 373.5 million (as of December 31, 2020) |

| Contact person |

Overseas Business Support Dept. |

| Number of employees | 472 (as of April 1, 2021) |

| Date of company foundation | November 1985 |

| The type of business |

|

International operation

| Number of employees for international operation |

13 | |

|

Overseas offices |

City, Country | Name of Company (if applicable) |

| Laguna, Philippines | Mitsubishi Chemical Aqua Solutions Co., Ltd. Philippine Branch | |

Modality of business transaction

Direct Investment

We are looking for direct business with the customers of our water treatment systems that produce drinking water from groundwater, surface water and city water and so on.

We can either sell the system itself or sell a service package with operation and maintenance to supply safe water continuously. We are also planning to offer a purchase scheme with less financial burden on the customer’s side.

Partnership

We are looking for a local business partner or a distributor who would actively support our business of water supply services, water treatment system sales and O&M services of such systems.

When we find a potential partner(s), we will transfer the technology, necessary for the work above.

Export of product

We can export our products such as water treatment system packages and related accessories, and also remote monitoring systems.

Attachments

Schematic illustration of the technology

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control

- Human Health Technologies : Public health